The right machine for your task

MOBILE AND COMPACT PIPE MACHINING

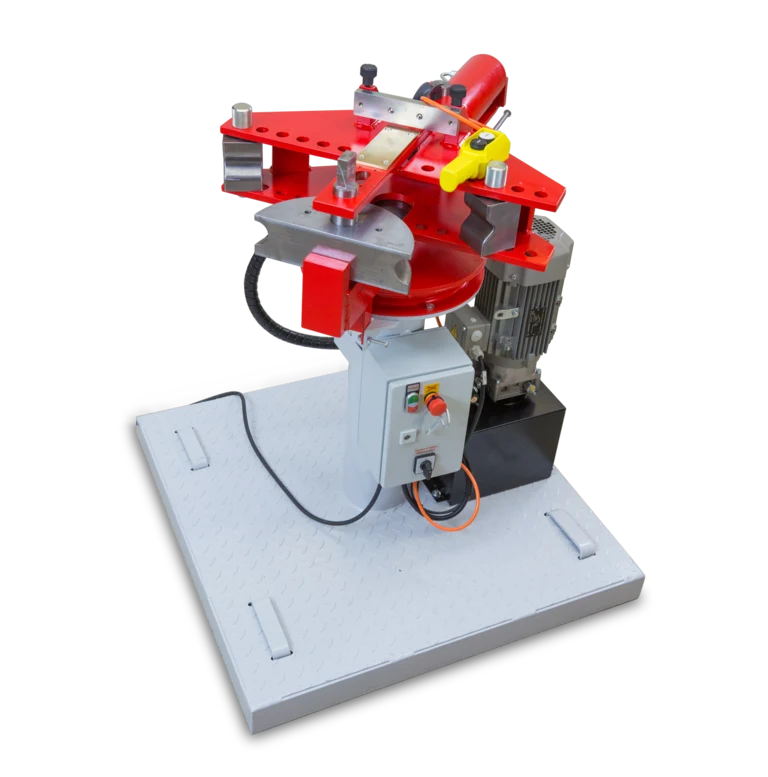

Type: MB 642

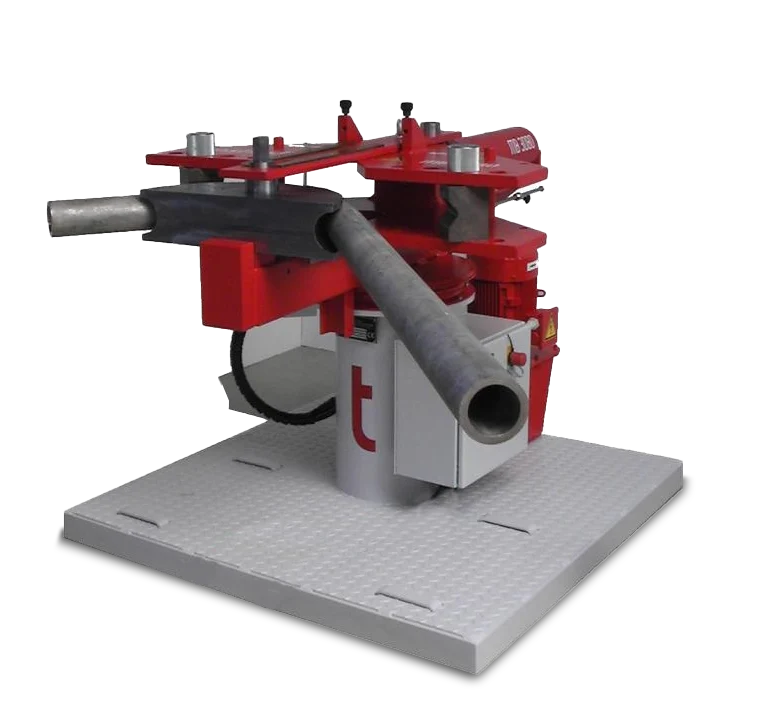

Type: MB 2060

Type: MB 3080

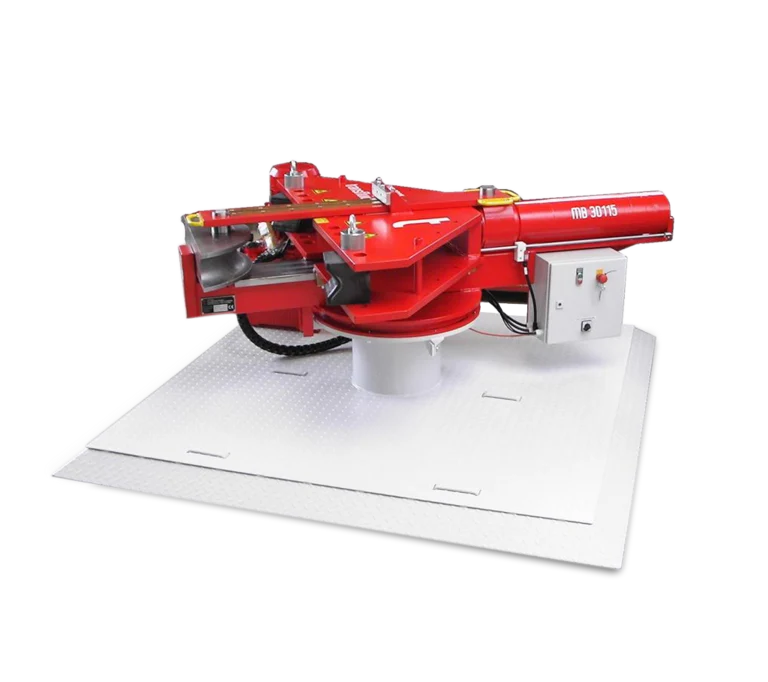

Type: MB 30115

| Range | 1/4" - 1 5/8" |

| Max. capacity | 1 5/8" x .191" (mild steel) 1 5/8" x .120" (stainless steel) 1" x .125" (Square section) |

| Max. Radii | 4.1" |

| Usable length | 5 ft 10 ft (standard) 15 ft 20 ft |

| Speed of bending axis | 13 °/sec. |

| Range | 1/4" - 2 3/8" |

| Max. capacity | 2 3/8" x .188" (mild steel) 1 3/8" x .120" (stainless steel) 1 1/2" x .120" (square mild steel) |

| Max. Radii | 15'' |

| Usable length | 15 ft 20 ft (standard) |

| Speed of bending axis | 35 °/sec. |

| Range | 1/4" - 3 1/2" |

| Max. capacity | 3 1/2" x .120" (mild steel) 3 1/2" x .072" (stainless steel) 2 1/8" x .157" (square mild steel) |

| Max. Radii | 9.4" |

| Usable length | 10 ft (standard) 15 ft 20 ft (special) |

| Speed of bending axis | 100 °/sec. |

| Range | 6-115 mm |

| Max. capacity | 115 x 4,5 mm (mild steel) 115 x 3 mm (stainless steel) on request (square mild steel) |

| Max. Radii | 360 mm |

| Usable length | 6096 mm (standard) |

| Speed of bending axis | 15 °/sec. |

The right machine for your task

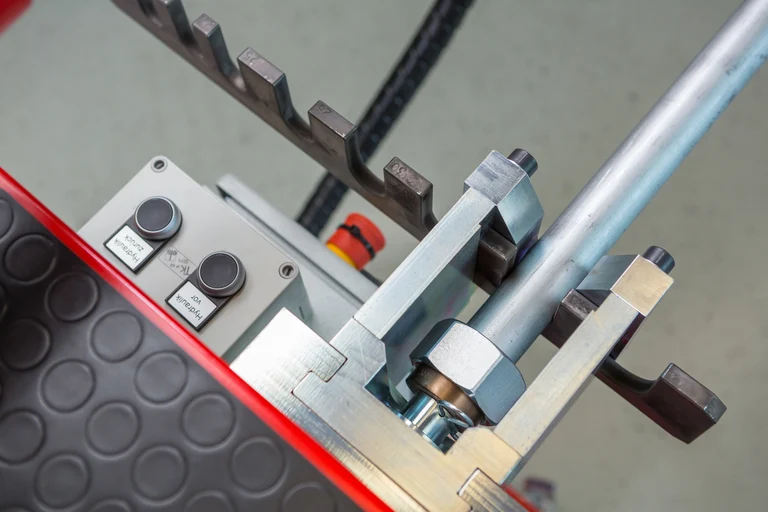

Stable, flexible and economical.

This series will win you over with its special stability and performance. Individual pieces and small series can be produced in an extremely economical manner with this machine concept. The use of high-value components ensures the machine‘s durability.

ALTERNATIVE DRIVE

Optionally a pneumatically driven variant for the offshore sector.