Automotive technology - solving complex problems more easily

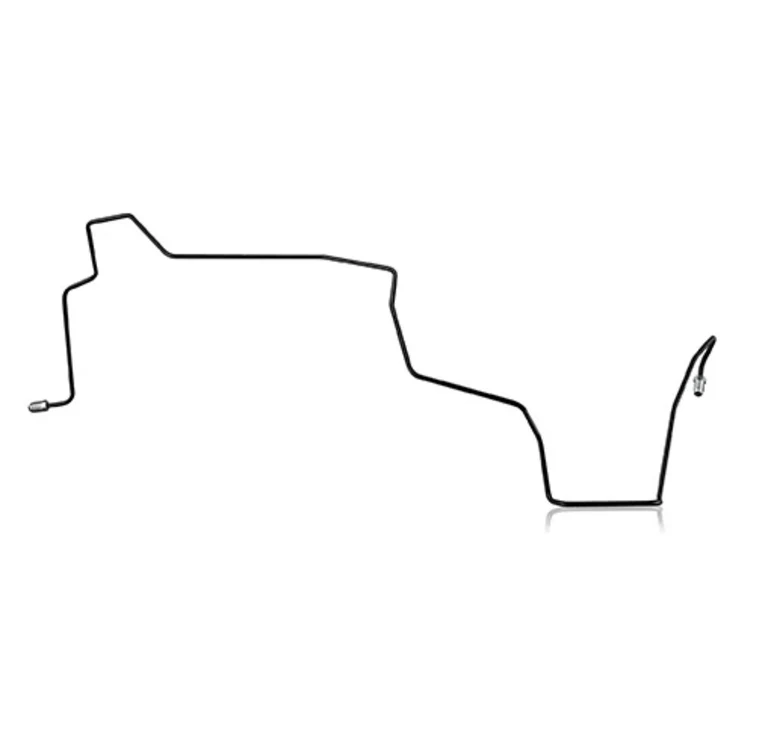

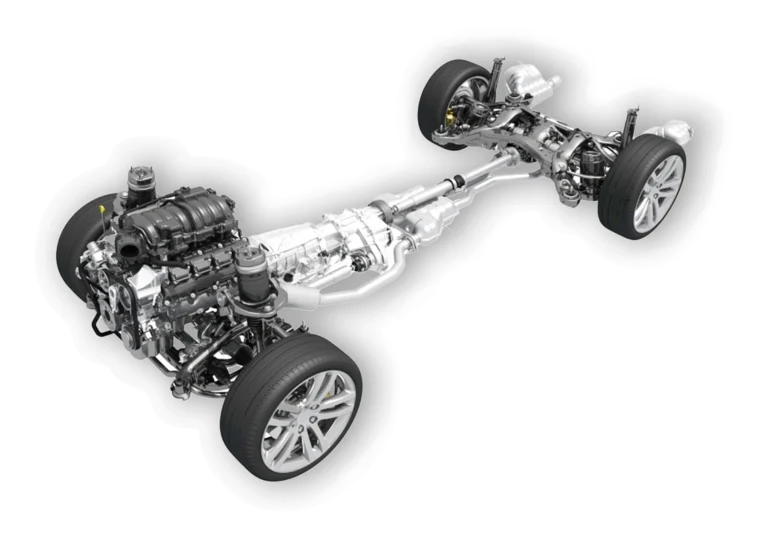

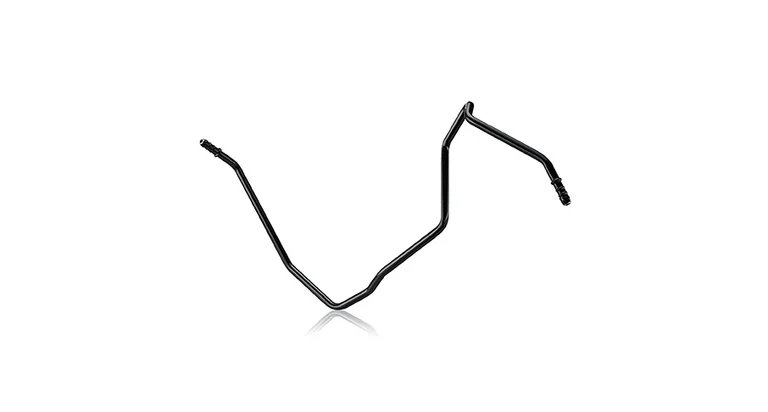

Sophisticated and precisely machined tubes for the numerous functional areas of a vehicle, such as brakes, air conditioning, exhaust system and steering, help you to optimally meet the high demands placed on your product.

transfluid offers client-specific solutions in the automotive industry, together with comprehensive expertise for all areas in this sector. Completely new challenges lie ahead with future technologies, such as fuel cells in electromobility.

production samples