Powerful pipe shaping and bending technology

create safe mobile hydraulics

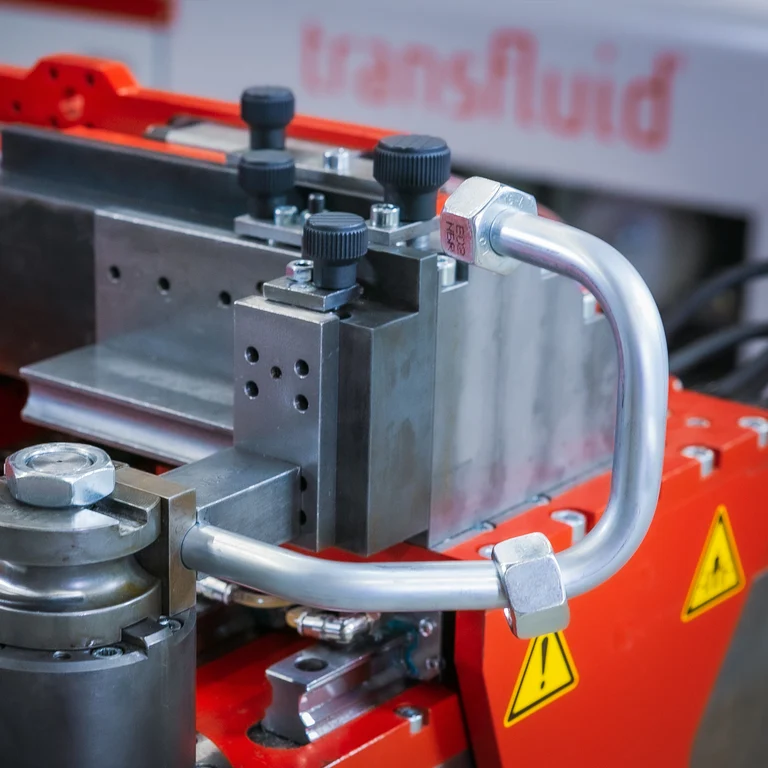

The extreme demands imposed on construction vehicles require them to have precision-fit pipework and reliable joints and connections on their hydraulic drives, which tackle of lot of very heavy work. Specifically designed to meet these challenges, we have developed our compact CNC pipe-bending machines. One example is our DB 642 R/L-CNC mandrel-bending machine that can even bend tubes with thick walls efficiently. With our mobile Type UMR pipe-shaping machines we can produce highly complex shaping geometries and secure connection systems in the hydraulic area, such as 37° or 90° flanges for flat-sealing O-ring connections (e.g. ORFS).