NEW FROM STOCK

Actual available stock & used machines

transfluid update !!!

More Power for Your Production – with significant tax advantages.

Why wait until next year if you can save taxes right now?

With a new transfluid machine, you not only invest in state-of-the-art tube processing technology – you also strengthen your financial performance.

Thanks to Section 179 of the U.S. Tax Code, businesses can benefit from substantial tax deductions when machinery and equipment are placed into service.

Up to $1,000,000 can be deducted immediately, with phase-out beginning at $2,500,000 in total qualifying purchases.

This means: faster write-offs, improved cash flow, and a strong incentive to modernize your production today.

Double the benefit – technologically and financially:

Increase your competitiveness with efficient, automated tube processing solutions while taking advantage of powerful tax incentives.

This is the ideal moment to upgrade your production with transfluid at your side.

Get in touch now and secure your tax advantages:

We will support you with personalized guidance for your investment planning.

When time is of the essence!

We always have a large selection of immediately available new machines, demonstration machines in mint condition and used machines in stock. Benefit from attractive offers for top-equipped-machines:

- All stock machines are immediately available and ready for use

- Demonstration machines with low operating hours

- Used machines in top condition

Get in contact with our experts.

Are you interested in one of our machines?

Get in touch with us – we’ll be pleased to prepare a non-binding quotation for you.

If you require additional equipment options or accessories, please don’t hesitate to contact us.

Daniel Burns

Office: +1 864.509.9245

t bend BENDING MACHINES

Highly efficient CNC bending technology for small and big bending tasks with the greatest precision.

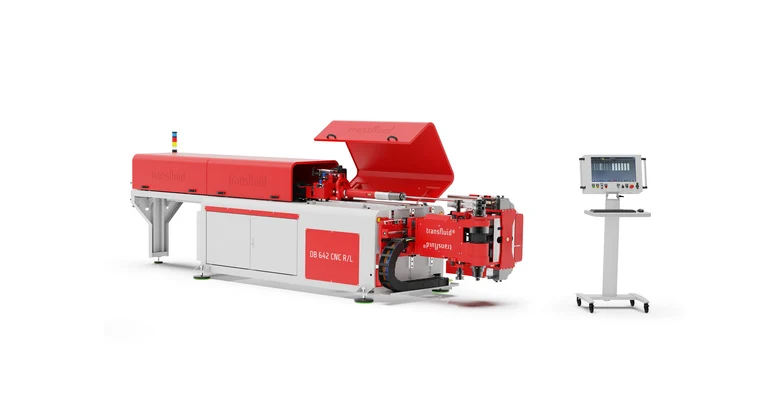

CNC - MANDREL BENDING MACHINE - TYPE R/L

With our clockwise/counterclockwise bending machines the most complex bends become reality with great accuracy. For pipes with diameters from 1/4" to 2 3/8".

| Model | Tube-ø | Max. radius |

|---|---|---|

| DB 622-CNC-R/L | 3/16" - 7/8" | 2.6" |

| DB 642-CNC-R/L | 1/4" - 1 5/8" | 6.6" |

| DB 2060-CNC-R/L | 1/4" - 2 3/4" | 7.1" |

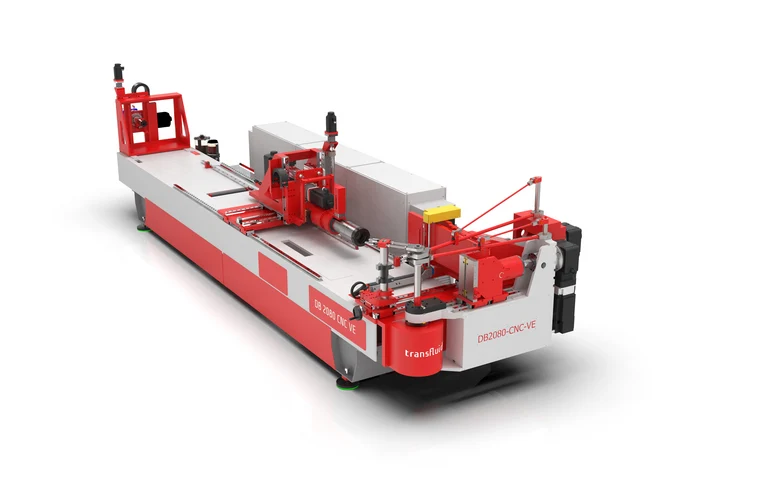

CNC - MANDREL BENDING MACHINE - TYPE VE

The solution for the future: highly dynamic and flexible, thanks to the 100 % servo-electric technology. For pipes with diameters from 1/4" to 6".

| Model | Tube-ø | Max. radius |

|---|---|---|

| DB 2080-CNC-VE | 1/4" - 3 1/16" | 9.4" |

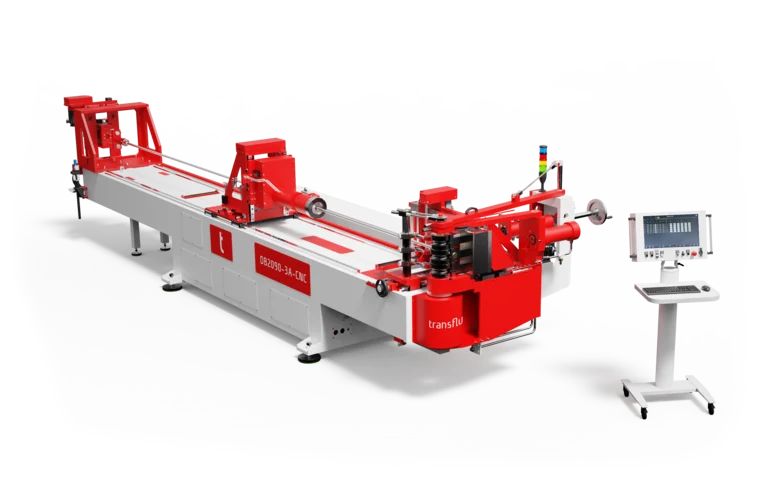

CNC - MANDREL BENDING MACHINE - TYPE 3A

Stable, flexible and economical. This series will win you over with its special stability and performance. A real power pack of a machine For pipes with diameters from 1/4" to 12 3/4".

| Model | Tube-ø | Max. radius |

|---|---|---|

| DB 2090-CNC-3A | 1/4" - 3 1/2" | 10.6" |

MANDREL BENDING MACHINE - TYPE K

Our compact mandrel bending machines are operated fully with hydraulics. Perfect bend quality with tight bending radii, from 1.5xD.

| Model | Tube-ø | Max. radius |

|---|---|---|

| DB 642-K | 1/4" - 1 5/8" | 4.1" |

| DB 2076-K | 1/4" - 3" | 6" |

t form TUBE FORMING MACHINES

Tube forming machines for short production times and outstanding results.

AXIAL FORMING MACHINE - TYPE REB

Accurate forming with fast tool change. Our type REB axial t form forming machines, with their compression power of up to 1,300 kN are particularly well-suited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit they will satisfy almost all requirements.

| Model | Tube-ø | Forming length | Cycle time |

|---|---|---|---|

| REB 420 | 3/16" - 3/4" | 2 3/8" | 2 – 3 sec. |

| REB 632 | 1/4" - 1 1/4" | 3 1/8" | 2 – 3 sec. |

| REB 645 | 1/4" - 1 3/4" | 3 1/2" | 3 – 5 sec. |

| REB 660 | 1/4" - 2 3/8" | 7" | 5 – 8 sec. |

ROLLFORMING MACHINE - TYPE SRM

Many forming options with one type of machine: forming, cutting, cutting after bending and threading. Our Type SRM forming machines are ideally suited for the production of challenging contours for sealing elements and for the generation of extremely good surfaces.

| Model | Tube-ø | Wall thickness max | Cycle time |

|---|---|---|---|

| SRM 622 | 3/16" - 7/8" | .035" | 4 – 10 sec. |

| SRM 1565 | 5/16" - 2 1/2" | .058" | 8 – 14 sec. |

COMBINATION MACHINE - TYPE REB/SRM

Highly demanding forming geometries in one work sequence: in our combination machines we have combined the benefits of axial and rollforming in one single system. Further processing step can be integrated without any problems.

| Model | Tube-ø | Forming length | Cycle time |

|---|---|---|---|

| REB/SRM 632 | 1/4" - 1 1/4" | 3 1/8" | 2 – 3 sec. |

| REB/SRM 645 | 1/4" - 1 3/4" | 3 1/2" | 3 – 5 sec. |

ROLLFORMING MACHINE - TYPE UMR

The type UMR tube forming machine and its special tumble method and contoured flaring mandrels guarantee high quality as standard. It produces perfect and mirror-like sealing surfaces when forming tubes up to a diameter of 325 mm.

| Model | Tube-ø | Wall thickness max | Cycle time |

|---|---|---|---|

| UMR 628 | 1/4" - 1 1/16" | .095" | 4 – 10 sec. |

| UMR 642 | 1/4" - 1 5/8" | .148" | 4 – 15 sec. |

t cut - CHIPLESS ORBITAL CUTTING MACHINES

transfluid machines deliver the highest cut quality and the workpieces can be processed without any further steps.

CHIPLESS ORBITAL CUTTING MACHINE - TYPE RTO

Our chipless orbital cutting machines make precise cutting results possible. Your tubes can be formed immediately afterwards. That saves time and money.

| Model | Tube-ø | Wall thickness | Cycle time |

|---|---|---|---|

| RTO 628 | 1/4" – 1 1/8" | .072" | 2,2 – 8,0 sec |